New Type 15T/D Complete Rice Mill Plant Introduction

Our new type 15T/D complete rice mill plants can process paddy rice into national standard white rice just in one process. It is one of the newly designed rice mill machinery by our R&D production team. It is suitable for milling the material paddy, the parboiled paddy rice, etc. It can get 600-900kg of white rice per hour. The capacity of the single machine can be customized according to your special requirements. So, it is the ideal paddy rice mill machinery for rice distributing stations, farms, and rice factories, as well as self-employment.

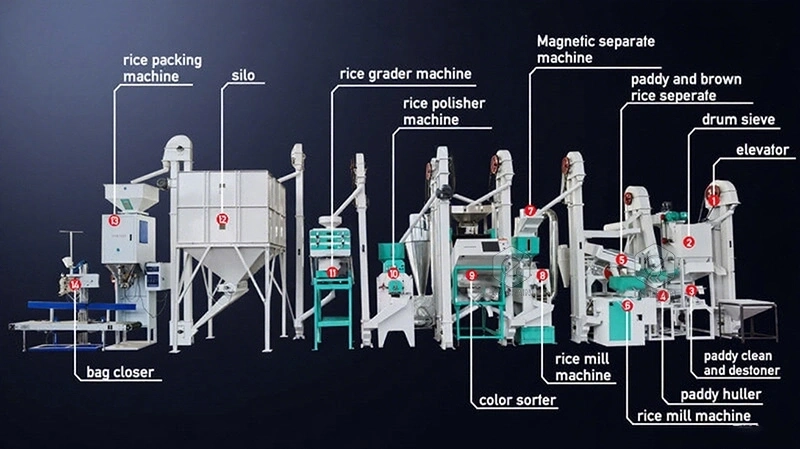

It is a complete rice milling plant containing a pre-cleaner, vibratory cleaning sieves, rice de-stoner machine, rice huller machine, paddy rice separator machine, rice mill machine, rice color sorter, rice polisher, rice color sorter, white rice grader, grain silo, and rice packing machine, etc. It uses the elevator to connect them and to make the whole line complete and automatically work.

This automatic rice milling plant with a daily capacity of 15 tons, can work continuously and efficiently. After the rice mill machinery is properly installed and debugged, the user only needs to feed the rice into the hopper, and then use the control box to operate the machine to process the rice. High work efficiency, automatic work, compact structure, convenient operation, and maintenance.

Full Rice Mill Plants Structure

Our rice milling machinery is a fully automatic rice mill plant that includes the entire process from paddy cleaning, stone removal, rice milling, rice hulling, grain separation, rice polishing, rice color sorting, and final rice packaging. You no longer need any other machines, you can realize the entire processing from paddy rice to the final finished white rice. Therefore, this complete set of rice milling equipment is very popular. Welcome, contact us for the details.

Full Rice Mill Plants Working Process

Drum sieve pre-cleaning: to remove impurities in paddy rice, such as straw, hemp rope, paper, clod, and other similar wastes to avoid engine failures. It will reduce the impurities in raw materials and increase the efficiency of the next cleaning process.

Vibrating cleaning sieves: to clean different size impurities

Rice destoner: Remove stones, stalks, and debris from paddy rice

2. Paddy Rice Husking

Remove the husk from the paddy and turn the paddy into brown rice

3. Gravity Paddy Separating

Separate the brown rice from the paddy by the difference between gravity and surface friction.

4. Rice Milling

Brown rice is processed into white rice through the first rice milling machine

5. Magnetic Separating

Remove the magnetic material in the rice, so as not to damage the subsequent rice milling equipment

6. Rice Color Sorting

Selecting the other colors of rice or mildew rice from white rice.

7. Rice Polishing

Make the white rice smoother and brighter

8. White Rice Grading

The broken rice in the finished rice is separated to improve the quality of the finished rice

9. Grain silos

Cache the produced white rice

10. Rice Packing

Set the weight of each bag of maters for packing according to your needs and pack the white rice in a bag.

11. Bucket Elevator

Using the bucket elevator to connect all the machines in a whole complete rice mill plant and automatic working.

Our Rice Mill Machinery Unique Advantages

1. Increase the drum sieve pre-cleaning, the cleaning efficiency is higher, thereby increasing the output of the whole machine

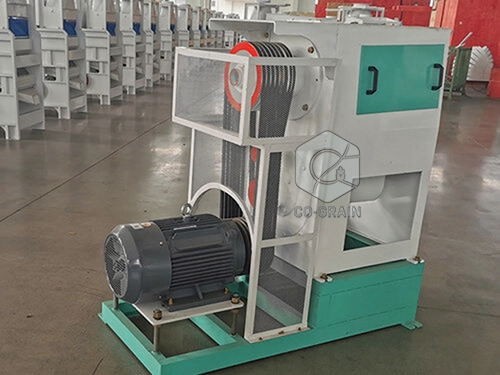

2. The shells of the rice mills used by other manufacturers are made of plastic, while our rice mills are all made of iron, so the whole machine has a longer service life.

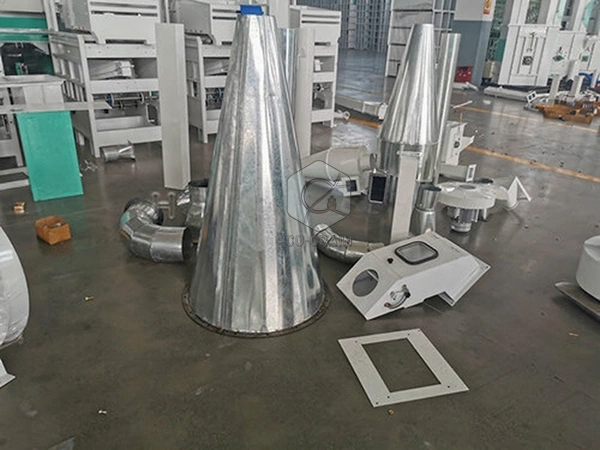

3. The dropping tubes of other rice mill manufacturers are made of iron, which is easy to rust and is not conducive to product safety. The dropping tubes of our rice mills are all made of stainless steel, which is more in line with food processing safety requirements.

4. The elevators used in our rice milling machine all use a separate motor base, and do not share the motor with other machines in the rice milling machine, so the production efficiency is higher.

5. The hulling machine adopts 8-inch rubber rollers, the hulling rate is as high as 85-90%, and the hulling rate is higher.

6. The screen area for cleaning and stone removal is large, and the cleaning efficiency is high.

Our Rice Mill Machinery Features

1. Fully automatic rice mill plant, less power consumption

2. Compact structure, small volume, high output, less broken rice production, high purity

3. The main body warranty is 12 months except for the spare parts

4. Easy to operate, we provide English version operation instructions and video operation instructions

5. Trusted & guaranteed the whole service with professional technical support before and after-sales

6. We have rich experience in building the complete rice mill plant abroad successfully and received a high reputation from our customers for the good quality and best price as well as professional technical support.

Rice Mill Machine Packing

The rice mill plant milling machine will be packed into a wooden case before into a container, it will guarantee the safety of all the machines. Our delivery time is 25 days after deposits, which also will depend on the order quantity.

Henan Co-Grain Machinery Engineering Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

Welcome Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Phone/Whatsapp: 0086-18339828199